Years ago, I was the product development manager for one of the big car audio wiring and accessory companies. This background provided me with a unique opportunity to test power distribution and overcurrent protection solutions in my lab before we brought a product to market. Though I’m not formally educated as an engineer, I did my best to apply logic and a genuinely scientific method to my evaluations. These experiences have made me somewhat obsessive about proper electrical system upgrades and overcurrent protection devices. Let’s look at fuses and circuit breakers and how they work.

What Is an Overcurrent Protection Device?

First, we need to define what a short circuit is. Pulling from memory, the definition I learned in auto shop while in high school was “a complete path through which excess current flows due to a lack of normal resistance.” If too much current flows in a circuit, the conductors may overheat and fail. When this happens, it’s usually in a spectacular fashion that involves lots of smoke and sometimes sparks and fire. For example, a short circuit across a car battery can result in thousands of amps of current flow for a second or two. This is enough energy to melt steel, copper, aluminum or pretty much anything conductive, including a watch or ring. Likewise, a short circuit can damage or destroy the voltage regulator in an alternator.

When we ask an installer to add an amplifier, remote starter, aftermarket lighting, heated seats or a new radio to our vehicle, those items need to be connected to a 12V power source. Those connections must be protected with an overcurrent device like a fuse.

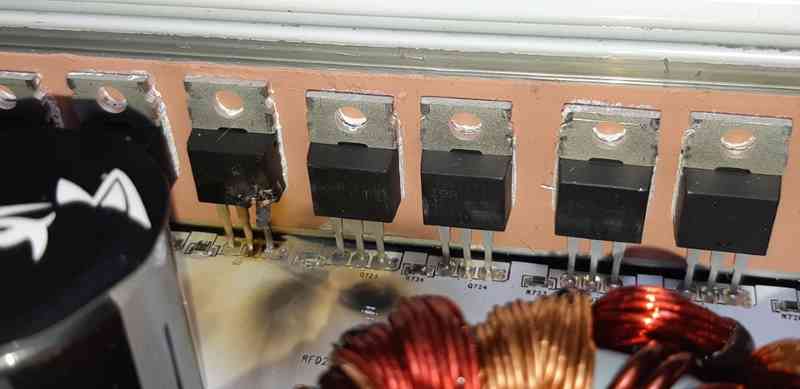

The purpose of the fuse is less to protect the added device added and more to protect the electrical system from a failure in the device. For example, if you have a high-power amplifier with a power supply with six or eight 30-amp MOSFETs and one fails and causes a short, chances are the MOSFET will be destroyed long before a fuse on the exterior of the amp can protect it. It’s most likely that an amp with that much current capacity will need a 100- or 150-amp fuse. If 100 amps of current flow through a 30-amp device, it will fail – magnificently. The amplifier protection fuses are there if there is a massive short where the power wire is connected directly to ground. You don’t want the power and ground wire to start smoking or catch fire.

Where Do Car Audio Systems Need Fuses?

Anytime there is a connection to a power source, an overcurrent device should be installed. The primary power wire for an amplifier connected to a battery under the hood needs a fuse. If there’s a battery in the trunk, the power wire run to the amplifiers or distribution block needs protection. If you’ve had a second battery added to the electrical system, all of the positive connections from the battery need fuses, including the feed to the alternator. These fuses need to be as close to the power source as possible to offer excellent protection.

Oddly, it’s rare to see a protective device on the wire connected to an alternator. While it’s unlikely that the wire will fall off the alternator, it’s not impossible. If a mechanic is replacing the alternator, allowing the positive wire to inadvertently touch the chassis is more of a probability than a possibility. This is a good example of why the negative battery terminal needs to be disconnected when the vehicle is being serviced.

I often think about the number of car audio fail posts I see on social media where an eight-AWG power wire for an amplifier is connected to the battery under the hood, then run through the door jamb, across the rubber seal and off into the trunk. That pinch point in the door jamb is eventually going to wear through the jacket on the wire, and it will short. It might take a long time, but it will happen. Having a protection device is SO crucial.

How Do Fuses Work?

In short, a fuse is a controlled weak link in the electrical system. A fuse includes a wire or piece of metal that’s designed to melt easily. This wire or metal strip has more resistance than the power wire used to connect the load to the power source. When a lot more current flows through the fuse than it’s rated for, it starts to get hot. This heat increases the resistance in the wire or piece of metal, causing even more heat to be created. Very quickly, the metal melts and the electrical load or short circuit will be disconnected.

Fuses used in car audio systems are rated based on current. Fuses have voltage ratings, but those are in place to ensure that the circuit functions safely. For example, a fuse won’t blow immediately if used in a higher-voltage circuit. With that said, other parts of a circuit may be at risk if the fuse isn’t rated for the correct voltage. At a high enough voltage, current may jump across the fuse terminals even when it has blown. Most automotive fuses are rated for 32 volts.

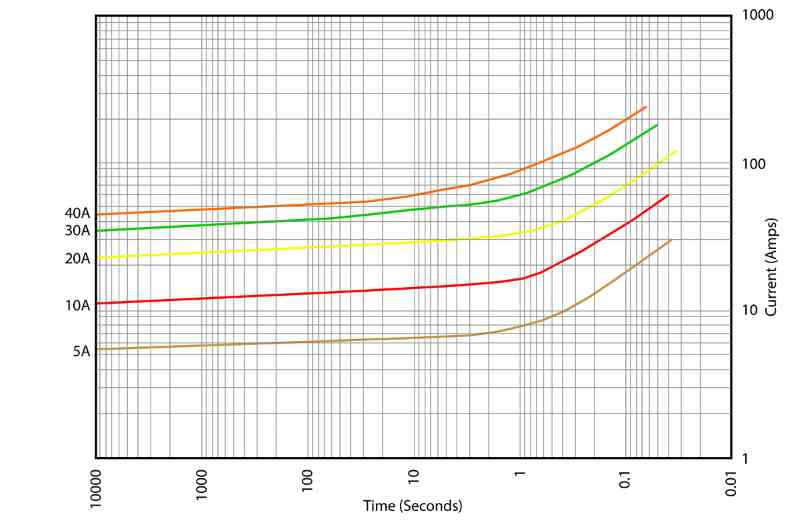

The current rating on a fuse is a nominal value. If you have a 30-amp fuse, it will easily pass 35 or 40 amps of current for short amounts of time. Have a look at the time-current characteristic curve graph below. This graph is for Littelfuse ATOF fuses. The green trace is for a 30-amp fuse. It can pass 35 amps of current for more than 10,000 seconds, or 2.7 hours. If we ask it to pass 50 amps of current under nominal temperature conditions, it will last about five seconds. If we ask it to pass 60 amps, it will blow in about one second.

Different types of fuses have different curves. For example, a 30-amp Littelfuse MIDI fuse, which is very similar to the Mini-ANL, can pass 50 amps of current for 40 to 50 seconds. At 60 amps, a MIDI fuse will last for about eight seconds. Given that the fuses are physically larger, they require more heat for the link to melt.

One last comment on fuses. They are designed to fail when the wire or metal link melts. As such, fuses perform differently depending on the ambient temperature. If the fuse is at the freezing point, it will be able to pass more current without failing than if it’s hot. A 30-amp ATO fuse is derated to 25 amps if it’s at 104 degrees Fahrenheit (40 degrees Celsius). As mentioned, the hotter the fuse gets, the more resistance it presents, which causes the amount of heat created by the current flow in the fuse to increase quickly.

One-Piece or Glass Fuses?

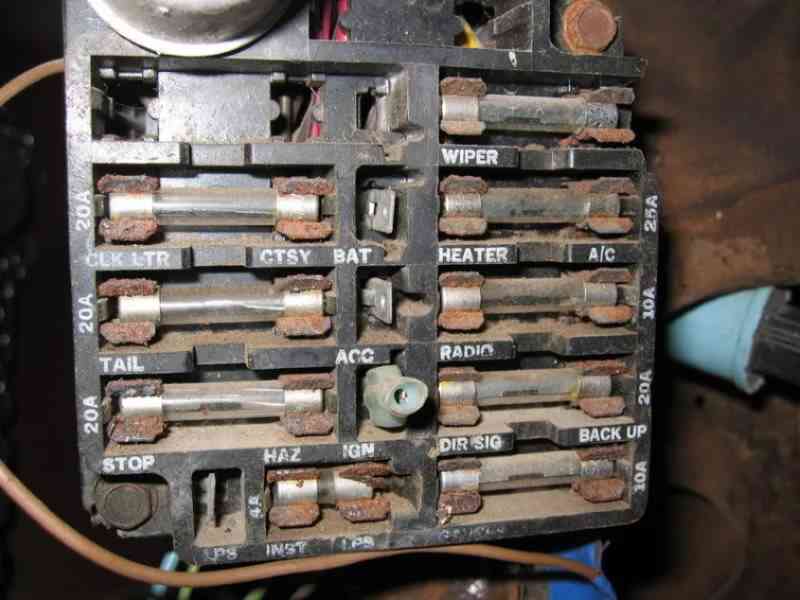

In terms of reliability, I have a strong preference for one-piece fuses. These fuses are available in either blade style or bolt-through solutions like ANL and Mini-ANL. All the current flows through a single piece of metal in these fuses. There are no connections other than to the fuse holder itself. The alternative is glass fuses like AGU and AGC. Most cars and trucks in the ’60s and ’70s had fuse panels loaded with AGC glass fuses.

A glass fuse is made of four parts: the glass cylinder, the top and bottom caps, and the fusible link. The link is soldered to the top and bottom cap. At least, it’s supposed to be. Unfortunately, I’ve seen at least a dozen AGU fuses over the years that didn’t have a proper solder connection to one end. While it looked fine, it wouldn’t pass current.

If you look carefully at the photo of the AGC fuse above, you can see a trail of solder running down one side of the tube. This fuse has either been overheated, or the solder trail was a manufacturing flaw. I randomly pulled this out of one of the hundreds of parts drawers in the lab.

Fuse Mounting Considerations

Another consideration in the choice of fuse style depends on how much current the circuit will be drawing. If a technician adds a low-current device like a line-level converter or a powered USB port, the device will likely only need one or two amps of current. In these applications, spade fuses like the ATO style work fine to protect the circuit. If you’ll be drawing moderate current levels, say, up to 30 or so amps, then a MAXI fuse is acceptable. I avoid any fuse that relies on spring tension at higher current draw levels to complete the circuit. You can read about the adventure I had with my friend’s Supra here.

So, AGC, AGU, ATO, and MAXI fuses are, in my opinion, not ideal for current draw levels beyond 20 or 30 amps. I prefer to be in complete control over how well current will pass from the wire to the fuse and back to the wire. As such, I always recommend bolt-down ANL and Mini-ANL fuses.

With an ANL or Mini-ANL fuse holder, the installer can torque the fastener to ensure that the connection with the fuse is tight. Making sure the connections to the fuse are mechanically secure is crucial. I can’t even think of the number of times I’ve seen melted fuse holders that installers blame on a bad design when in reality, it was a loose wire connection.

Fuses or Circuit Breakers?

The wiring and accessory company I worked for didn’t sell circuit breakers. This was a conscious decision based on the potential failure mode of these devices. Failure mode is an engineering term that refers to what happens when a device or system doesn’t operate as intended. In the context of this discussion, the failure mode of an overcurrent protection device refers to it not interrupting current flow. There have been documented cases of circuit breakers welding themselves permanently closed when an extremely high current passes through them. As a company, the last thing we wanted to hear was that the protection solution we offered failed to protect a vehicle or its components. So the company decided to offer ANL and Mini-ANL fuses as our exclusive protective solution. We’ll look closely at how circuit breakers work in a future article.

In the meantime, make sure you have fuses on all the positive connections your installer has added to your battery. Your local specialty mobile enhancement retailer can help you choose a fuse solution that will keep your vehicle safe.

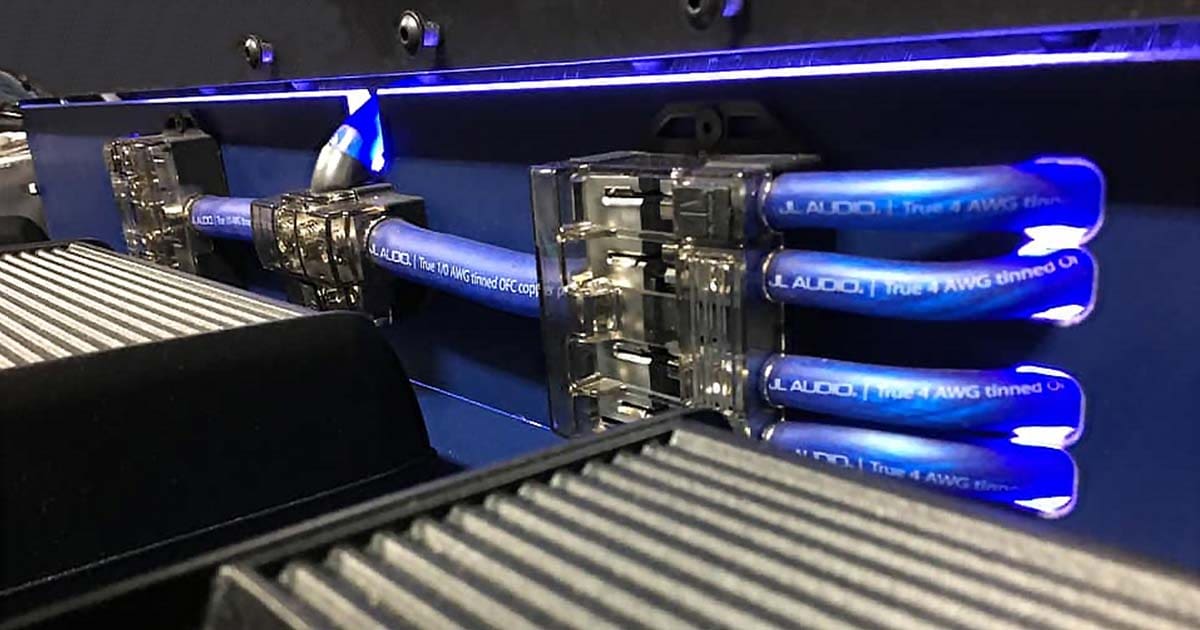

Lead-in Image: Thanks to John Brettle for sharing this image of a JL Audio powered, wired and protected installation he created.