It’s time to dispel another unsubstantiated car audio myth! This time, we’re talking about claiming that you can’t ground an amplifier directly to the battery in a vehicle. Perhaps it would add to the clarity of the statement to say that many inexperienced installers think the ground wire for the amp has to go to the chassis of the vehicle. Many of these statements also add, “Connecting directly to the battery will cause noise.” All of these statements are nonsense. Let’s check them out.

How Electricity Flows

Whether you subscribe to the conventional current theory that electricity flows from the positive side of a power source through a load and back to the negative terminal, or to the electron theory that holds that electrons flow from negative to positive, what matters is that an electrical circuit is a loop. Your load, be it a light bulb, radio or amplifier, needs to have two electrical connections. Power flows from the electrical source through the load and back to the source again. The current in both conductors is equal.

Our vehicles have two power sources: the battery and the alternator. The battery is there to start the vehicle. It feeds a high-torque electric motor that spins the engine when you turn the ignition key to start. Once the engine starts, the alternator takes over the operation of the vehicle. Technically, you can remove the battery from the car and it will continue to run. Don’t try this, though, as many new vehicles monitor current flow in and out of the battery to control the alternator’s function. Once the engine is running, the alternator recharges the battery.

Having an Amplifier Installed in Your Vehicle

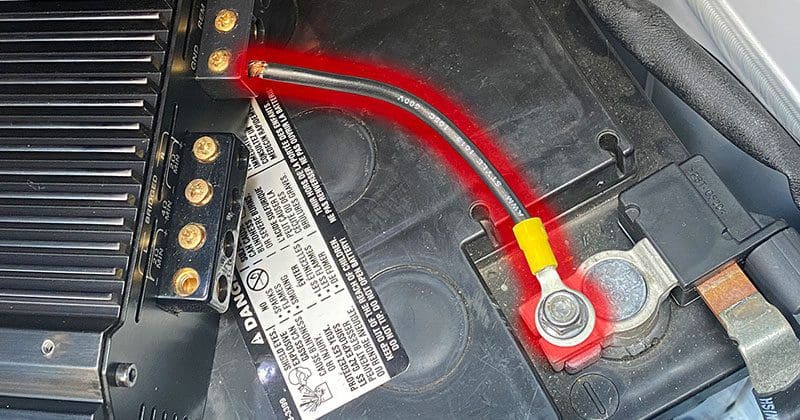

In the “good old days,” installing an amplifier in a car or truck involved having your installer run a large-gauge wire from the battery’s positive terminal through a fuse holder or circuit breaker to the positive terminal of the amplifier. The wire from the amplifier’s ground terminal would be bolted to the chassis of the vehicle.

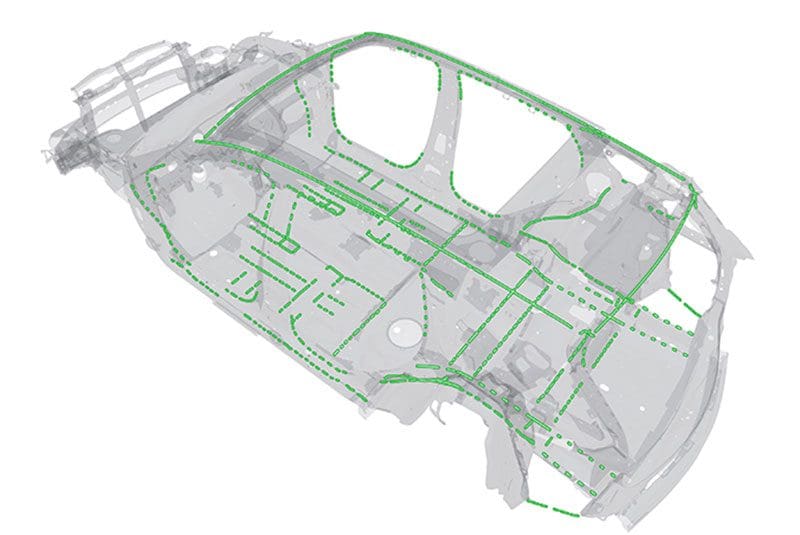

Until about a decade ago, most cars and trucks were built with steel, and the chassis or unibody components were spot-welded together. As a result, there was often enough surface area between the panels to allow current to flow from the ground of the amp back to the negative terminal of the battery or alternator.

What’s Wrong with a Chassis Ground?

A few things could go wrong when using the chassis as a ground point for a high-power amplifier. First, the connection to the chassis needs to be secure and reliable. Second, your installer needs to brush or grind away any paint, rustproofing or undercoating from the metal before they drill a hole to make the connection. Third, the chassis may not be a direct electrical return path to the battery.

The ground connection needs to be secure. Because the cable is of a reasonably large gauge, it can experience moderate loads during acceleration and braking and from the vibrations associated with regular driving. This stress can loosen the connection and cause intermittent behavior or damage.

You’d think removing paint, primer and coatings would be easy, but the number of poor grounds we see is amazing. In some cases, especially with cars that are painted silver, some primers and corrosion-resistant coatings can look similar to bare metal.

In many modern vehicles, lighter metals such as aluminum are used in vehicle construction. These materials don’t conduct electricity as well as a high-quality copper conductor. What’s more concerning is that many new vehicles are assembled with high-strength adhesives and even two-sided tapes from companies like 3M, Dow Chemical and Henkel. These materials are not electrically conductive.

Ohm’s Law in 20 Seconds

Whenever current flows through a device or conductor with resistance, a voltage is produced across that device. In the case of a piece of wire, the resistance is typically low, so very little voltage is wasted. When the current flow is significant, we can see several volts across the wire, and it will heat up. To calculate the voltage drop across a resistance, multiply the current flow (in amps) by the total resistance of the device (ohms). For example, 2 amps of current flowing through a 4-ohm resistor results in 8 volts being produced across that resistor.

Proper Amplifier Grounding

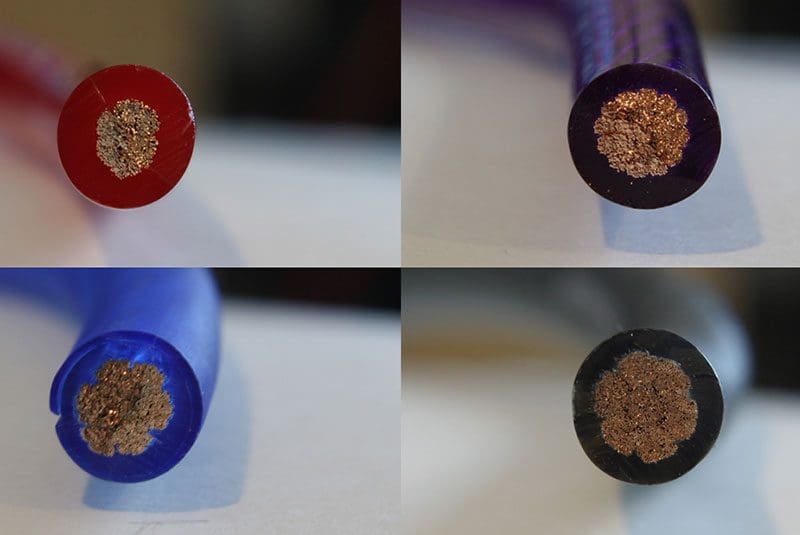

Feeding your high-performance amplifier with the power it needs means delivering as much voltage as possible to the power terminals. If the amplifier draws a significant amount of current, then your installer will need to use large-gauge conductors to prevent voltage losses due to the resistance in those conductors. This same logic applies to the ground return path. A test performed several decades ago by one of the engineers at JL Audio in Miramar, Florida, showed that most vehicle chassis have a resistance equivalent to a piece of four AWG cable. Modern vehicles are much worse.

Let’s say you have a good quality 1,400-watt amplifier like the ARC Audio ARC1000.4 DSP we tested a few months ago. This amp produced 1,406 watts of power (at 1% distortion) when provided with 13.37 volts at the power terminals. It drew 137.1 amps of current to deliver this power (at an impressive 76.7% efficiency). If your vehicle had a 16-foot run of all-copper, CTA-2015 compliant, four-AWG power cable to feed the amp, there would be a voltage drop of 0.588 volts across the length power cable. The ground return path (assuming it has the same resistance) would result in a similar loss of voltage at this current level. Your electrical system would need to be able to supply the battery with 14.546 volts and have a spare 137 amps of current capacity available. For a full-sized sedan or truck, these numbers are quite reasonable. So, you might be able to get away with using the chassis as a ground – if you know it’s all-steel from front to back.

When Grounding Goes Wrong

Now, what happens when we run into a vehicle where the chassis isn’t a good ground? Perhaps it only has the current-carrying capacity of a piece of 12-AWG wire. At low to moderate volume levels, our amplifier won’t draw much current. If the amp is a modern Class-D design, it will likely have a driver IC that includes low-voltage support for start-stop vehicles. If so, the amp won’t shut off even if the voltage drops below 6 volts for a moment.

Let’s run the math again. We want about 1,400 watts and will attempt to draw 137 amps of current. With a chassis with the current-carrying capacity of a 12-AWG conductor, 3.74 volts would be lost across our chassis connection. The amp will likely stay on, but it certainly isn’t going to produce 1,400 watts when it only sees 10.8 volts. In our experience, aluminum and bonded-construction chassis have even more resistance, and the voltage drops are significantly worse.

The Parallel Ground

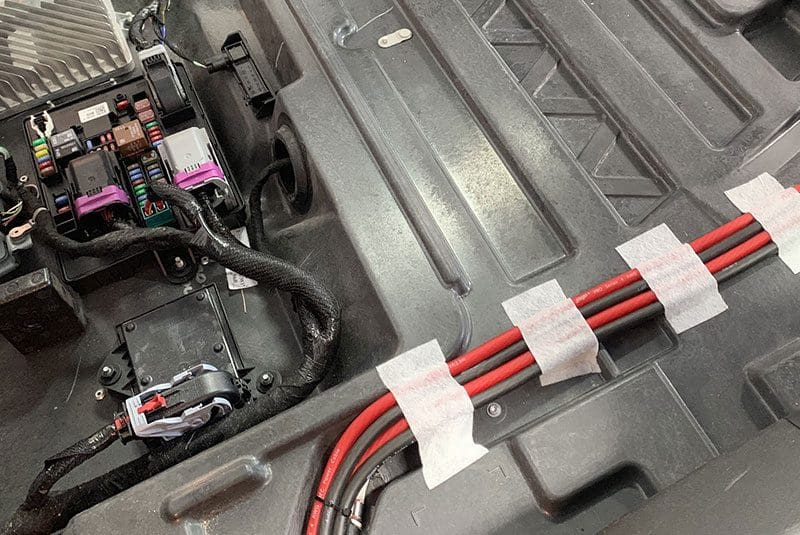

Going back to the testing done by the folks at JL Audio, they propose that your installer run what they refer to as a parallel ground. The installer can bolt the ground lead from the amp to the chassis, then run a conductor of the same size as the power leads to the battery’s negative terminal.

In this scenario, the worst-case condition is that the new ground wire carries all the current from the amp, and you have a minimal voltage drop. More likely, some current will also flow through the chassis to the battery, and this results in less voltage being wasted than if it wasn’t grounded at the rear of the vehicle.

Stop The Noise

We can’t fathom where the myth about grounding to a battery and getting noise came from. Perhaps there was an installation that had a ground loop of some sort. Ground loops can (and do) happen when the chassis is used for grounding.

Let’s dispel this myth with one sentence. Think of all the marine audio systems and stereos in Corvettes that you’ve seen over the years. Fiberglass certainly can’t be used as a ground return path. These vehicles don’t have any noise problems associated with how power is distributed.

When it comes time to have an amplifier installed in your vehicle, you can improve its efficiency by providing it with as much voltage as possible. This means minimizing voltage losses due to power cable or ground return path resistance. Upgrading to larger or better wiring and having the installer at your local specialty mobile enhancement retailer run a parallel ground is a great way to ensure that your system will function reliably.