The Consumer Technology Association, formerly known as the Consumer Electronics Association, has updated the CTA-2006 Standard for Testing and Measurement Methods for In-Vehicle Audio Amplifiers to revision D. The original standard, known as CEA-2006, was introduced to help eliminate bogus amplifier power claims and make it easy to compare car audio amplifier power production and performance. The document has been revised four times, with the current version D providing very specific processes for power, frequency response, noise and distortion testing. In this article, I’ll explain the process for each key test so you will have a better idea of what to watch for when shopping for an amp for your car stereo system.

Test Criteria

The ANSI/CTA-2006-D document starts with several test criteria for all measurements. The first condition requires that test loads (resistors) be within 5% of their target impedance. For a 4-ohm resistor, the value can vary from 3.81 to 4.2 ohms. The resistors must be non-inductive, so their opposition to current flow can’t increase at high frequencies. This type of resistor is more expensive but is required to ensure that measurements taken at anything above bass frequencies are accurate.

The second requirement involves the amount of voltage available to power the amplifier. CTA states that car audio amplifiers should be fed 14.4 volts with a tolerance of +0/-5%. Again, the deviated voltage must be published with the power measurement. Amplifiers designed for other voltages, such as 24 or 48 volts, comply with the standard. Still, once again, the test voltage must maintain the +0/-5% tolerance, which must be specified in the power rating.

All testing will be performed with all channels driven simultaneously with equal signals. Therefore, crossovers, equalization and other preamp features should be off during testing.

The final condition we’ll discuss is setting the amplifier’s sensitivity or gain control. The CTA-2006-D standard states that this control should be set to its minimum level for all testing.

Frequency Response Measurements

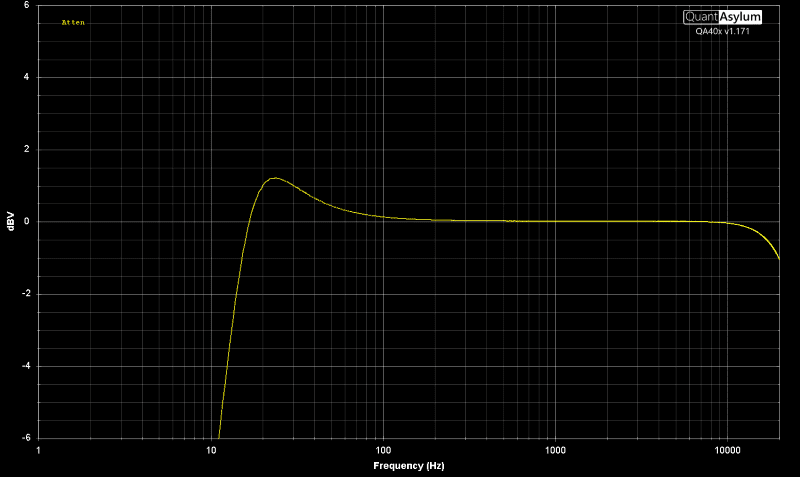

The standard for frequency response testing is to specify the upper and lower frequencies defined by the half-power points when producing 1 watt of power into a 4-ohm load. This level is equal to the output of the amplifier being down by 3 dB. Manufacturers are welcome to provide additional specifications, as long as they state the tolerance. It’s common for higher-end products to include -1-dB limits.

Continuous Amplifier Power Measurements

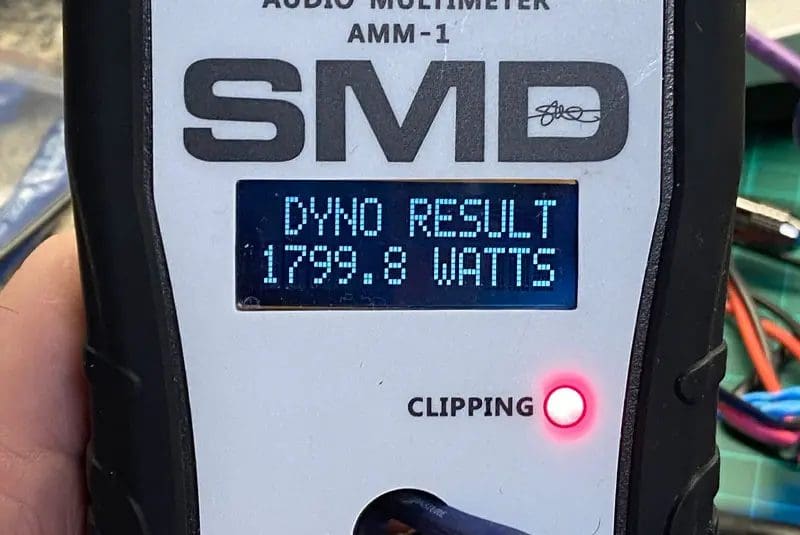

Amplifier power measurements will be taken at 1 kHz for a wide-bandwidth amplifier and at 50 Hz for subwoofer amplifiers. If an amplifier isn’t designed to function in these ranges, then a test frequency in the center of the operating bandwidth should be used. The test duration for power output must be at least 15 seconds. If the amplifier cannot produce the desired test level because of power supply or thermal considerations, the test level should be decreased until this requirement is met.

The output signal from the amplifier must contain no more than 1% total harmonic distortion plus noise. If the amplifier cannot produce power with less than 1% THD+N, then the minimum distortion must be specified with the power number.

Finally, the power production specifications may include additional load impedances such as 2, 1 or 0.5 ohms. All loads must be within the 5% tolerances. If a measurement is made with the amplifier outputs in a bridged configuration, that must be stated along with the power measurement.

Dynamic Power Measurements

As many modern car audio amplifiers have undersized power supplies, a dynamic power rating and continuous rating are allowable. For dynamic power measurement, the amplifier would be fed a test signal that includes a 1-kHz 20-cycle burst followed by at least 480 cycles of rest. For bandwidth-limited amplifiers, such as those designed for subwoofers, the test would use a 50-Hz test frequency with 10 cycles, then rest for 20 cycles at a minimum level of at least -20 dB. In both cases, the amplifier must produce the rated dynamic power output with the test cycle repeated five times, and the measured power for the burst must not exceed 1% THD+N at any time. The rating shall be stated based on the channel producing the least power.

Maximum Dynamic Power

The standard outlines a test to state maximum dynamic power. This test is similar to the dynamic power measurement testing but allows for 10% THD+N. An amplifier manufacturer may also note the total maximum dynamic power by adding all the channels’ tested values.

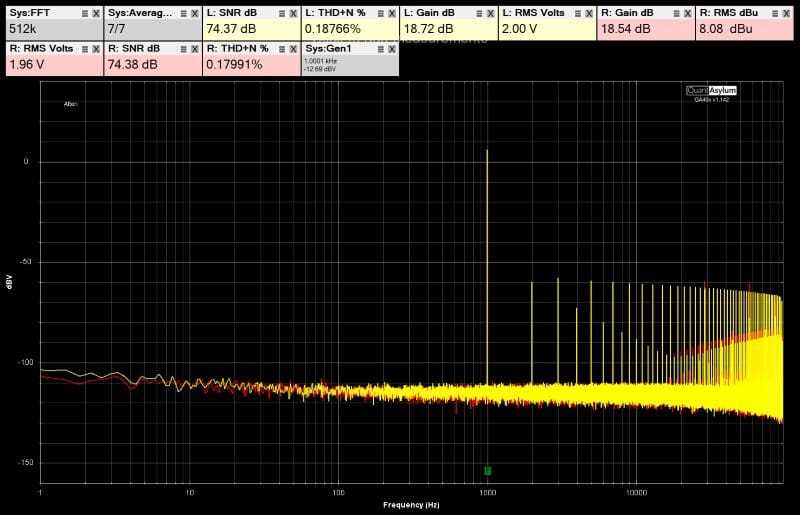

Signal-to-Noise Ratio Measurements

The CTA-2006-D standard provides two options for signal-to-noise ratio measurements. The ratio may be provided relative to the power level specified in the continuous power measurement test or referenced to 1 watt of power. The 1-watt standard makes comparing amplifiers much easier, as the levels are all identical. However, comparing S/N ratio measurements at the maximum continuous level is only helpful if two amplifiers produce very similar power levels.

In both cases, the CTA-2006-D standard requires that an A-weighting filter be applied to the reference signal after its level is determined. Further, the published S/N ratio shall be that of the amplifier channel that performs the worst.

Total Harmonic Distortion Plus Noise Measurements

The standard again allows for two test criteria for total harmonic distortion plus noise measurements. These measurements can be taken at the rated continuous power level or 1 watt into a 4-ohm load. The standard specifies that harmonic content needs only be measured up to 20 kHz. The THD+N should be measured at one-third octave intervals across the amplifier’s published operating bandwidth. The worst measurement across this range shall be the value posted.

Editorial Comments

Here are some thoughts on the testing defined by the ANSI/CTA-2006-D standard.

I’m afraid I have to disagree with the option to test noise and distortion at continuous power levels as the sole specification. The CEA-2006 standard was created to simplify comparing car audio products. I think the 1-watt reference should be required, and a secondary measurement at the rated continuous power level should be an option.

Second, testing at 14.4 volts seems enthusiastic. Many vehicles can’t produce this much voltage, especially at high current-draw levels. A voltage of 12.5 volts is much more “real world.”

The point about all channels in an amplifier being driven equally is crucial. With so many compact amplifiers on the market, the current delivery capabilities of many power supplies are inadequate to drive all channels. Many companies cheat this rating system by configuring the amplifier for a two- or three-way actively filtered system.

In reference to signal-to-noise ratio testing, I haven’t been using an A-weighting filter for my Test Drive Reviews. However, I’ll add that measurement in the future, since it only requires a single click in the test interface software.

Lastly, I can’t entirely agree with all the measurements being taken with the gain control set to its minimum. Some amplifiers have noisy input stages. As such, their signal-to-noise ratio measurements in real-world applications where the sensitivity control needs to be increased might not be accurately represented using this minimum setting. The CTA-2006-C standard indicated that the gain control be set at its mid-point for all channels for THD+N testing and at a 1-volt level for signal-to-noise testing.

Nevertheless, having standards for testing that are easily reproducible across all audio products is crucial to providing consumers with accurate information. If you’re shopping for a car audio amplifier, make sure the products you choose indicate that they’ve been tested in compliance with the CTA-2006-D standard or that the information provided with each specification follows their guidelines for the testing. Drop by a local specialty mobile enhancement retailer today to find a high-quality amplifier that will sound great!