Who wouldn’t want to buy the loudest, most efficient speaker possible to upgrade their car audio system? A speaker that does a better job converting electrical energy into sound reduces the load on the vehicle’s electrical system, right? Well, efficiency is just a single parameter in the myriad values that describe how a speaker works. Let’s take a super-techy look at how speaker efficiency is calculated and explain how it relates to audio system design and performance when upgrading your car audio system.

All Speaker Parameters Matter

I read an article the other day in Stereophile magazine about a company called NWAA Labs. They built an anechoic chamber in a retired nuclear power plant. Aside from the stunning background noise level of -43 dB SPL at 1 kHz, the facility can provide accurate frequency response measurements from 25 Hz to 10 kHz. On the topic of speaker measurements and correlation specifications, Ron Sauro, owner of the NWAA Labs facility, said, “You have to spend some time learning how to look at the different measurements and determine how they all integrate with each other. You have to integrate them in your brain and understand that if you take this particular parameter and combine it with this other parameter, it’s going to give this type of result. That takes time and experience. You can’t just throw a graph out there and expect that somebody who has absolutely no experience integrating these measurements will understand what they’re seeing.”

Keep this in mind as we move through the article.

Calculating Speaker Efficiency

The relative low-frequency performance of a typical moving coil loudspeaker can be predicted using a set of electro-mechanical values known as the Thiele/Small parameters. Looking at a set of speaker Thiele/Small parameters, you will likely see efficiency values. The first will be n0 (lowercase n with a subscript 0). This calculated value provides a percentage efficiency (when multiplied by 100). The formula to calculate n0 is (9.7822 x (10^-10) x Vas x (Fs^3)) ÷ Qes. The Vas parameter is the equivalent compliance in liters, and Fs is the resonant frequency in hertz. Qes is the electrical Q of the speaker and is stated without units as it’s a ratio. In simple terms, this calculation tells us how much of the power sent to a speaker will be converted to sound and how much will be wasted as heat.

The first thing you should notice is that resonant frequency plays a significant role in the calculation as its value is cubed (multiplied by itself twice) in the numerator of the formula.

You might also be wondering why the driver’s area doesn’t appear to play a significant role in driver efficiency. It does. It’s just buried a little bit. The formula to calculate a speaker’s equivalent compliance (Vas) is 0.00014 x Sd^2 x Cms, where Sd is the effective radiating area of the driver in square centimeters and the Cms is the compliance of the driver suspension in millimeters per Newton. So, a larger driver or a more compliant (softer) suspension both increase the Vas of the driver. With the Vas in the numerator of the efficiency calculation, we know that more cone area and a softer suspension increase efficiency. So far, this is all very logical.

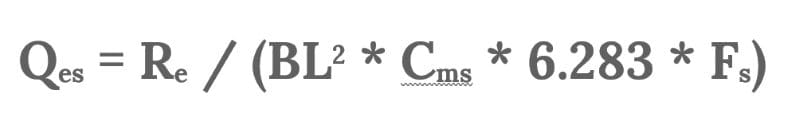

Working against driver efficiency is the driver’s calculated electrical Q (Qes) as it’s in the denominator. If we look at the formula to calculate Qes, the whole topic starts to make even more sense. The formula to calculate Qes is Re ÷ ((BL^2) x Cms x 6.283 x Fs). Looking at this equation, we have the DC resistance of the voice coil (Re), the driver’s BL product and the resonant frequency of the speaker (Fs) as the key considerations. Increasing resonant frequency will lower the Qes, raising the efficiency in the previous formula. An increase in the motor force BL (which is the product of the strength of the magnetic field multiplied by the length of wire in the field) also lowers Qes and raises efficiency. A more compliant speaker suspension lowers the Qes and boosts efficiency. Finally, increasing a speaker’s voice coil DC resistance, logically, increases the Qes of the driver and reduces the efficiency.

Look at the Big Picture!

Let’s step back and look at this as a whole. More cone area increases efficiency. A more compliant suspension increases efficiency. A higher resonant frequency increases efficiency. Lower voice coil resistance increases efficiency. Now, think about what we’ve described. This doesn’t sound like a subwoofer to me. A 10-inch midrange driver with a very compliant suspension would be efficient, right? A perfect example would be the Hertz SV 250.1 SPL midrange. This driver is part of the SPL Show series and has a calculated n0 of 3.347%, a 1-watt/1-meter efficiency of 97.39 dB SPL and a 2.83-volt/1-meter efficiency of 101.2 dB SPL.

Rockford Fosgate has a similar 10-inch midrange driver called the Punch Pro PPS4-10. The Punch Pro 10-inch has a much lower resonant frequency (53.5 hertz compared to 90 for the Hertz) but also has a more compliant suspension (35.2 liters compared to 20 liters), so its efficiency is 2.48% 96 dB at 1-watt/1-meter. The trade-off between the two is that the Rockford Fosgate driver has about 50% more excursion capability at 4.6 mm vs. the Hertz at 3 mm. The extra weight of that taller voice coil winding would have contributed to the change in efficiency.

Enclosure simulations predict that the Punch Pro driver will give us a more midbass output at the expense of a few decibels of efficiency. If you don’t have dedicated midbass drivers in your system or subs that can play above 250 hertz, this would be the best option for your audio system. If you have midbass drivers in the system, then the added efficiency of the Hertz driver is beneficial. Remember what we said before we started this discussion: Every speaker parameter interacts with others, and no single consideration outweighs any other. One of these drivers isn’t “better” than the other as they fit a different application.

When it comes to speaker design, the low-frequency output is the typical trade-off for increased efficiency. A higher Fs value will mean less deep bass. A stiffer (less compliant) suspension also means less deep bass.

Modeling a Hypothetical Speaker

Let’s start with the Hertz SPL Show SV 250.1 speaker and do some simulations in BassBox Pro. I chose this driver because I have a complete set of Thiele/Small parameters for it.

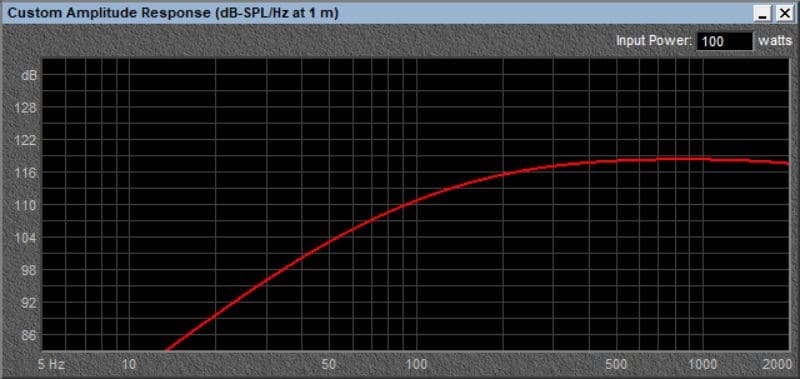

We’ll model the driver in a 3-cubic-foot sealed enclosure as this replicates a typical car or truck door installation. The software predicts an F3 frequency of 190.1 Hz and a peak SPL of 118.2 dB SPL at 870 hertz.

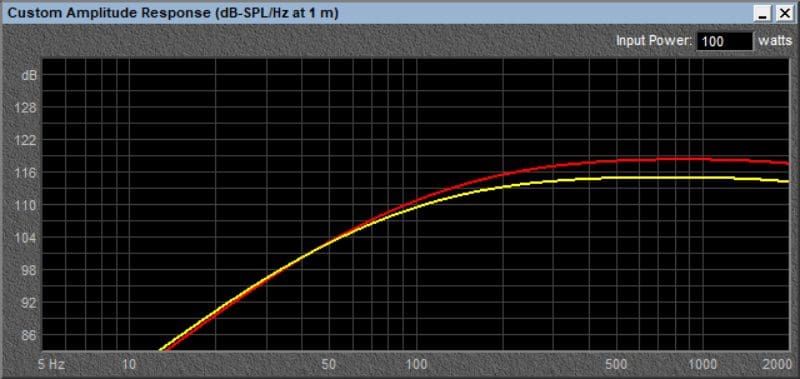

What if we had a hypothetical driver with a similar design but with a lower resonant frequency because of a heavier cone assembly? I changed the resonant frequency value from 90 to 70 hertz and kept the Vas the same at 20 liters, the voice coil resistance the same at 3.3 ohms, then let BassBox Pro recalculate the remainder of the parameters.

Our efficiency has dropped from 3.347% to 1.575% or 97.39 dB at 1 watt to 94.12 dB. In the same application, the -F3 frequency of the enclosure is now 109.2 hertz, and the peak SPL is 114.9 dB with 100 watts of power. There are two ways to look at this new driver: It’s not as loud in the midrange, which is the scientifically correct observation. The other way to look at it is to say that it produces more bass relative to the maximum midrange output.

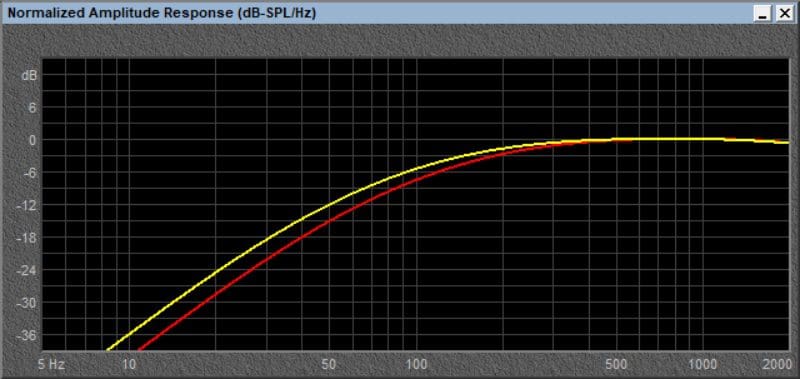

If we look at the predicted frequency response relative to the peak output, we see the second description of a driver that produces more bass relative to the midrange energy.

In reality, your installer could use a digital signal processor to attenuate the midrange output of the more efficient driver to produce a similar real-world response. This method has the benefit of requiring less power to reach the same midrange frequency output levels. Could you boost the bass response in the original driver to yield the same thing? Sure, but you will need to consider that the driver still has a maximum power handling and excursion rating, so there is a limit to how much power you can send the speaker at low frequencies. Bottom line: It’s six of one, a half-dozen of the other.

We could go on and on for a week simulating and comparing different drivers with different parameters to find one that gives us the midbass and midrange performance we want so that the speaker’s output will blend with the subwoofer system we have in mind. Here’s what you need to know: Driver efficiency increases aren’t a free lunch. You rarely get more output without some other aspect of the design changing. If the engineer developing the driver knows how to offset a motor strength gain to maintain low-frequency performance, they will likely come up with something impressive.

Drop by your local mobile enhancement retailer today to find out what they offer in terms of high-efficiency drivers, and be sure to ask them about what’s best to use with your existing audio system.