Once again, we approach a discussion of the laws of physics and how they affect the electrical systems in our cars and trucks. The enemy of all power transmission systems, be it the battery and alternator to the amplifier in your vehicle or the nuclear power station or hydroelectric dam across the state to your home, is resistance. I saw a power wire sizing chart earlier this week that had me rethink how car audio systems are wired, so I thought we’d take another look.

Ohm’s Law and Wasted Power

Ohm’s Law states that for every amp of current that flows through a resistance of 1 ohm, 1 volt is produced across that resistance. If we lower the current, less voltage is produced. If we reduce the resistance, less voltage is produced. We are typically limited to 14 volts from a fully functional alternator in our cars and trucks. If the wiring between the alternator and the amplifier has resistance (and it does), some of the voltage is wasted across the wire and doesn’t reach the amp. Most aftermarket amplifiers in car audio systems have loosely or completely unregulated power supplies. As such, the amplifiers can produce more power if fed more voltage. Conversely, if we starve them for voltage, the maximum power they can produce decreases.

Power Wiring and Voltage Loss

A member of the Motorsport Wiring Alliance Facebook Group posted the chart below. The folks at WireCare provided him with the chart in response to an inquiry about the conductor’s current carrying limits. What’s unique about this chart is that it considers conductor size based on temperature rather than voltage drop. Why is this important? When a conductor heats up, its resistance increases. The increased resistance produces more heat, which creates even more resistance. It’s easy to see that this can quickly result in a runaway situation.

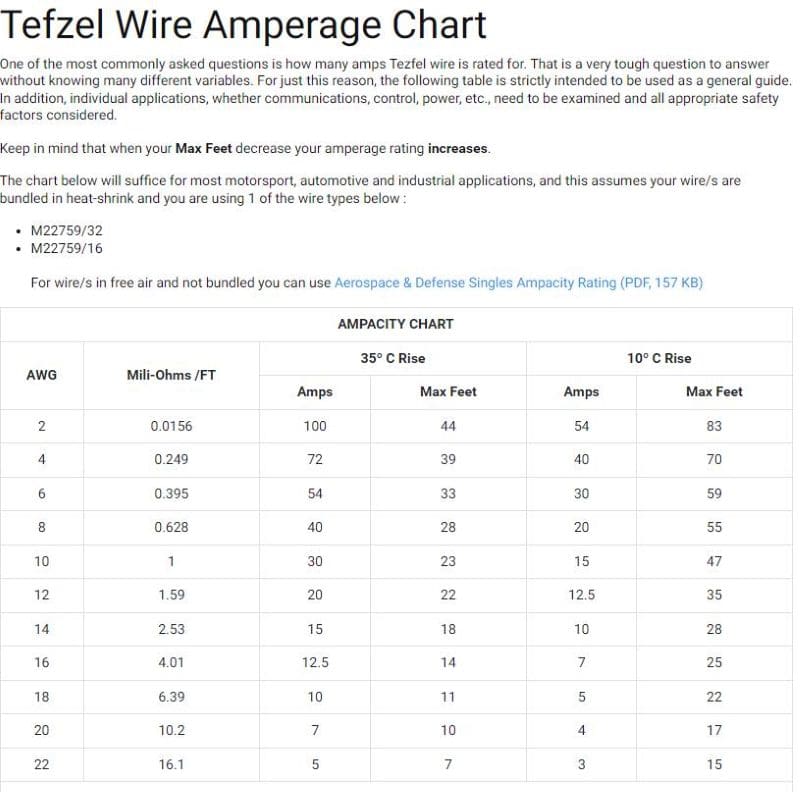

Now, before we get into a discussion about why choosing the correct wire size is essential, let’s talk about Tefzel wire specifically. If you’re accustomed to the typical wiring used for car audio upgrades, Tefzel is entirely different. This type of wire uses an ethylene tetrafluoroethylene copolymer (ETFE) jacket that can withstand temperatures up to 150 degrees Celsius. The primary power wire most car audio folks use has a PVC jacket and is rated for around 105 degrees Celsius.

It’s worth noting that Tefzel is a brand of ETFE and not specifically a brand of wire. When referring to Tefzel wire, the name describes the type of jacket on the wire. Tefzel is a type of ETFE resin and is sold as a raw plastic material in pellet form. Tefzel is also used in heat-shrink tubing, valve linings and biomedical equipment. Tefzel is a Chemours Co. brand, just like Teflon, Viton and Freon.

Tefzel is the standard for aviation wiring and custom wire harnessing that you’d find on any professional-level race car. A key advantage to Tefzel is that the shielding is very thin and durable, which results in smaller-diameter wire bundles. Further, the ETFE jacket doesn’t contain chlorine, which produces a lot of smoke when it burns – a key consideration in aeronautics applications. The downside is that it’s expensive. But, as they say, you get what you pay for.

A secondary benefit of the thin jacket is the ability of the wire to dissipate heat quickly compared with a conductor with a thick jacket. Allowing heat to escape to the air around the wire helps keep the resistance down, which minimizes voltage losses and improves efficiency. However, if you look at the above chart, the ratings are not directly comparable to typical car audio wiring in dissipating heat.

Let Your Power Wire Be Free!

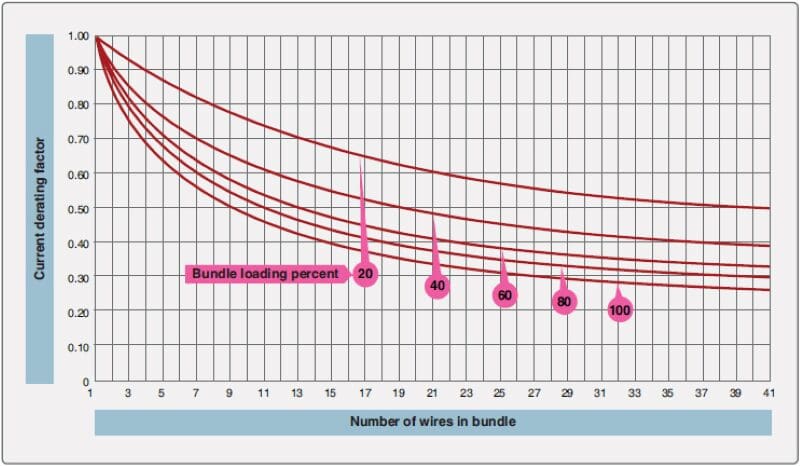

If you’re feeling particularly geeky, I recommend browsing NASA’s Re-Architecting the NASA Wire Derating Approach for Space Flight Applications document. In short, bunding many wires together can dramatically reduce their ampacity as heat generated in the conductor cannot escape the wire bundle easily. If you have a bunch of wires zip-tied together, they could present more resistance and consequently waste more energy than if each were out in the open with nothing touching them. From their research, a single 26 AWG conductor in free space could handle up to 4.7 amps of current and not exceed 200 degrees. When that same conductor was at the core of a bundle of 32 other wires, the maximum allowable current was 1.9 amps to reach a similar temperature. What’s the takeaway? Routing wiring away from heat sources will dramatically improve its current carrying performance.

This chart shows how the current handling capability of wiring decreases as more and more conductors are bundled together.

Power Wire and Heat Calculations

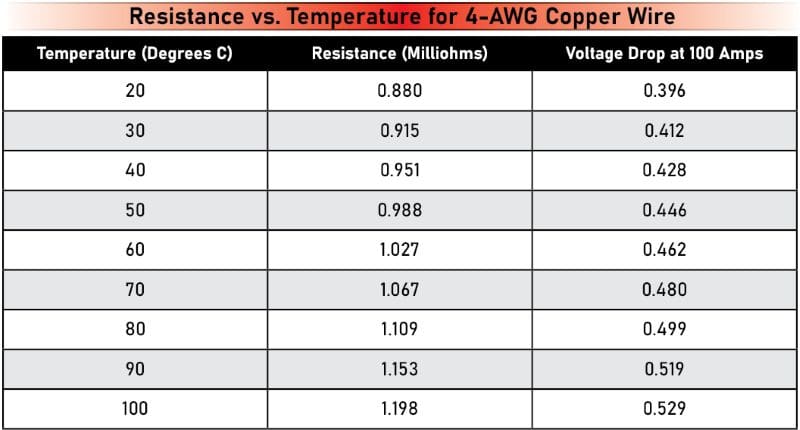

It’s common practice to consider all-copper 4 AWG power wire suitable to deliver up to 100 amps of current to an amplifier. Assuming the wire meets the ANSI/CTA-2015 Mobile Electronics Cabling Standard, 1 meter of 4 AWG should have no more than 0.88 milliohm of resistance. Assuming we usually need about 4.5 meters of wire to run from the battery to an amplifier in the trunk, we’d have a drop of 0.396 volt across the wire when 100 amps pass through it. Assuming the ground path has a similar resistance, that’s another 0.396-ish volt of drop. So we’ve lost about 0.8 volt from whatever the alternator produced.

I’ve measured dozens of copper-clad aluminum amp kits over the years. The best of those kits had a resistance of 1.43 milliohms per meter, and the worst I’ve tested had 3.37 milliohms per meter. So if we attempt to draw the same amount of current through those conductors, we have a voltage drop of 0.6435 and 1.517 volts, respectively. Add the drop of the return path, and you have a total of just over a volt and almost 2 volts for the dramatically undersized 4 gauge CCA wire.

The Tefzel wire chart describes an appropriate wire size for a given operating temperature range. In the case of their 4 AWG wire, their wire has an even lower resistance of 0.816 milliohm per meter. Drawing 100 amps through 4.5 meters of their wire results in a voltage drop of 0.367 volt. Honestly, that’s not worth the added cost. It’s also not the point of this discussion.

Tefzel rates the ampacity of their wire based on its operating temperature. According to their chart, 72 amps of current through Tefzel 4 AWG will raise the wire temperature by 35 degrees. Some simple math tells us that the wire dissipates 4.23 watts of energy per meter at that current level. For the maximum temperature to increase by only 10 degrees, they state that 40 amps is the maximum, which is 1.31 watts per meter. If we reverse the math, a 4 AWG car-audio-style all-copper power wire is only suitable for 38.55 amps of current to produce a temperature increase of 10 degrees. If we accept the 35-degree temperature increase, we max out at 69.35 amps. What about the CCA wire? The “good” CCA wire could pass 54.4 amps of current for the 35-degree rating, and the woefully undersized CCA is only good for 35.45 amps.

The issue with exceeding the ampacity rating of the wire is that it heats up. Pure copper has a temperature resistance coefficient of 0.00393. This means that for every increase in temperature of 1 degree Celsius, the resistance of the wire goes up by 0.393%.

As you can see, the effect of a conductor getting hot can dramatically increase its resistance. For example, at 100 degrees C, 4 AWG has more resistance than a conductor with an equivalent size to 5 AWG at 20 degrees.

Thankfully, we play music, not test tones, through our audio systems. Because of the dynamic nature of music, we get an averaging effect that dramatically reduces the power an amplifier needs to produce. Assuming you aren’t playing basshead music, it wouldn’t be unreasonable to consider that the average amplitude of a rock track would be about 12 dB, which equates to a 16x reduction in required power. In the context of our wire size discussion, if the maximum current your amp would draw is 100 amps, the average might be down to around 6.25 amps. Of course, there are a LOT of variables in that statement, but even if the average is 25 amps, you have a significant safety margin.

Don’t Starve Your Car Audio Amplifier

The first takeaway is that 2 AWG power wire needs to be much more prevalent in car audio applications. For example, a 1,500-watt amplifier that’s reasonably efficient would work well with 2 AWG wire.

Secondly, if you want your amplifier to produce all the power it claims, you must choose a high-quality power wire large enough for your application. The average power produced by an amplifier might be well below the maximum ratings, but that doesn’t mean you might still be limited when the peaks happen. Don’t skimp on power wire size or quality. A great way to add some reserve energy is to have the technician working on your car install a high-quality stiffening capacitor near the amplifier. Consult with a local specialty mobile enhancement retailer when choosing the correct power wire for the installation they’re performing.