When it comes to car audio product reviews, and specifically, BestCarAudio.com Test Drive Reviews, how I measure amplifier power is a topic that needs some consideration and contemplation. Who would have thought that measuring how much power an amplifier produces could be a controversial subject? The reality is, many factors come in to play as we quantify the capabilities of an amplifier. Here’s my take on the subject.

Power Ratings and Distortion Levels

Every car audio amplifier on the market is capable of being pushed beyond its capabilities to the point that it can add significant distortion to the audio signal it’s amplifying. This limit is typically based on the maximum voltage that the output switching devices have to work with. If you ask for more, the peaks of the audio signal are cut off and a huge amount of harmonic content is added to the signal to create what looks like a square wave. Clearly, if an amplifier’s output doesn’t closely resemble the signal you fed into the amp, then it’s not doing its job.

The CEA-2006-C standard, which we’ll delve into later in this article, defines the maximum allowable distortion in the output signal to be at a level of 1%. In terms of an interpretation, this means that there would be harmonic content at a level of 40 dB below the stimulus signal. I can assure you, especially with test tones, this is very audible. For our Test Drive Reviews, we’ll be using a maximum distortion level of 1%.

Distortion and the D’Amore Engineering AMM-1

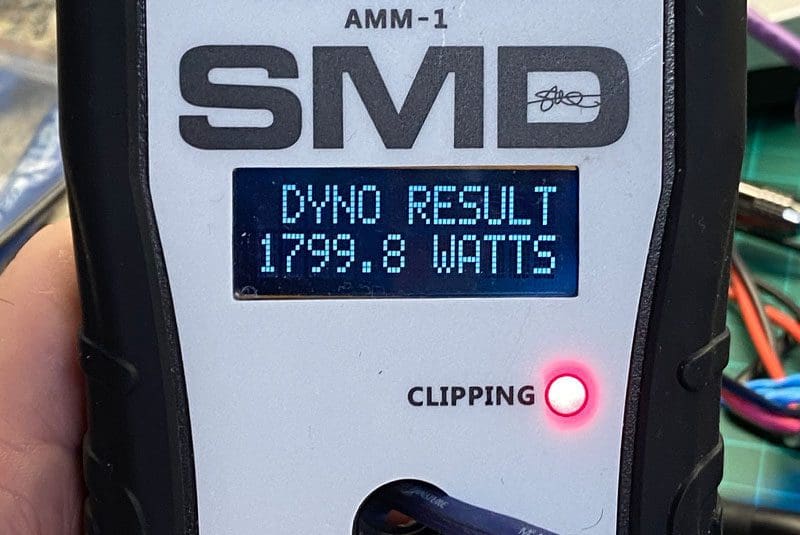

Maybe I should have stated this earlier, but I will use a D’Amore Engineering AMM-1 meter to measure amplifier power. This impressive handheld device measures the AC current and voltage going to a speaker or dummy load simultaneously to calculate power. The AMM-1 does not include a distortion detector but instead has a clipping indicator. When we assume “max power” from an amp happens at clipping, we see very different measurements than if we use a 1% distortion level. As such, I’ll also use my QuantAsylum QA401 audio analyzer to monitor the test signal, then cut things off when the distortion levels reach 1%. This takes some time but will yield repeatable results. Should we get into a situation where the amplifier produces more voltage than the QA401 can handle, I can create a voltage divider network or switch to my D’Amore Engineering DD-1 distortion detector to define the cutoff limit.

So, there we go. Car audio amplifier power testing will be determined when the output reaches a distortion level of 1%.

Let’s Talk About the ANSI/CEA-2006-C Specification

Created as the CEA-2006 standard, this specification outlines several criteria that were necessary to make it possible for consumers to compare power ratings from different amplifier manufacturers. The basics of the standard include the power supply voltage to the amp, the load that the amp is connected to and of course, as I just outlined, the amount of distortion allowable in the signal.

Where the topic of power measurements gets complicated and controversial is with respect to the supply voltage. The CEA-2006-C spec defines 14.4 volts as the standard. Personally, I think this is a little high and 13.6 might have been a better choice. Nevertheless, it’s a standard, and that should be fine, right? Yes and no.

A few companies make amplifiers that use regulated power supplies. Without getting too technical, this design functions to set a very specific rail voltage in the amp that’s independent of the supply voltage. If the supply voltage drops, the power supply works harder to maintain the rail voltage. If the power supply is increased, the amp doesn’t have to work as hard. In an unregulated design, which is common to most amplifiers on the market, the rail voltages are a multiple of the supply voltage. So, more supply voltage means the amp can produce more power before reaching the point that the signal clips.

The problem with the 14.4-volt specification is that some companies feel that it penalizes them for their regulated power supply designs. I’m not sure I’d consider it a penalty, but competing products with unregulated designs may produce more power. It’s all sort of silly though, since it takes a massive difference in power to increase the output of a system by a noticeable amount. For example, an amplifier that produces 180 watts per channel is only about 1.1 dB louder than an amp that produces 140 watts. Nevertheless, people continue to think that the 180-watt amp is “way better” than one that produces 140 watts. By the way, 140 watts and 180 watts are about the difference between measuring the output of an amplifier powered with 12.5 volts instead of 14.4 volts.

A second reason the 14.4-volt spec is a questionable choice is that it’s nearly impossible to deliver that voltage to an amplifier, especially when it’s drawing lots of current. On my bench, the power supplies (in their boost mode) rest at about 14.5 volts. If an amplifier is drawing roughly 130 amps of current, I usually see about 13.9-14.1 volts by the time cable losses and supply regulation conditions are considered. In a car where dozens of other devices are loading the electrical system, you might be lucky to see more than 13 volts at the amp, even if the vehicle rests at 14.4V. In most cases, the voltage dips into the 12-, 11- or 10-volt range. Sure, if you have an upgraded alternator and more batteries, this will improve – but what percentage of customers are willing to go that far? Maybe 1% of 1%? Probably a lot less than that.

Nevertheless, we need to make a decision for Test Drive Reviews. To try and “publish the big numbers,” I’ll leave my power supplies in boost mode and feed the amps as much voltage and current as I can. Usually, this will be in the 13.75- to 14.25-volt range. I’ll specify the test voltage and the power ratings so that everyone reading knows all the conditions.

What Is Power?

This last topic is near and dear to my heart and one that I love to debate. Let’s start this off with the definition of power. According to the International System of Units (SI), the base unit for power is the watt. One watt of power is equivalent to the work done by one joule of energy over a period of one second. By the way, one joule is equivalent to the heat created or work done when one amp of current flows through one ohm of resistance. It’s this time constant – one second – that I get hung up on. Is two amps for a half-second the same amount of work? I guess it is. Nevertheless, this brings up the discussion of dynamic versus continuous power ratings.

If you listen to stereotypical rock music, the dynamic power requirements are more significant than if you listen to electronic music created with synthesizers. The energy required to recreate the sound of the pedal hitting the skin of a kick drum doesn’t last very long. Conversely, playing the lowest note on an upright bass, a piano or a pipe organ can last for anywhere from a half-second to several seconds. Your amplifier needs to be able to maintain an appropriate amount of power delivery over the entire time. As such, I don’t have any interest in dynamic power ratings.

The test for dynamic power capabilities of an audio amplifier involves playing a tone burst that lasts 20 milliseconds, then allowing the amp to rest for 480 milliseconds, then repeating. In my opinion, if an amplifier’s dynamic power capability is significantly better than its constant power output potential, it wasn’t designed with a power supply that is adequately capable of supplying current.

When I test an amplifier, I’ll be using steady-state tones. Whether they last a few seconds or a minute, the numbers I provide will show the amp’s continuous power output rating.

Power Ratings on Multi-Channel Amplifiers

A few amplifiers on the market are designed with an integrated digital signal processor with the intent that they will power woofers, midrange drivers and tweeters. In the case of these amplifiers, the channels driving the small speakers will likely need 10 to 20 dB less output than those driving woofers.

For monoblock and two- through six-channel amplifiers, I’ll always test the samples with all channels driven to 1% distortion, unless there is a specific request from the manufacturer. Those additional measurements will be added in addition to the base “all channels driven” numbers.

Test Bench Standards Are Crucial

As I review more and more products, I’m sure there will be scenarios where we need to accommodate unique designs and applications. Since the purpose of the Test Drive Review is to convey as much information about a product’s functionality and performance as possible, I’ll always do what’s needed to accommodate each scenario. Shortly I’ll have a similar post about measuring distortion and noise in amplifiers. Keep your eyes peeled for that.