If you were to ask a professional what type of wire is best for connecting a car audio amplifier to the battery in your vehicle, they would tell you to use an all-copper conductor. What’s the alternative? Because of its significantly lower cost, many car audio systems use copper-clad aluminum (CCA) wiring. When talking with the product specialist helping you design your car audio system, you’ll want to ask whether the shop will use all-copper conductors. This article will discuss a few methods to test wire to determine its composition and explain the importance of using copper conductors.

Copper versus Aluminum Wiring

Why do professionals suggest copper over aluminum wiring? The most popular argument is conductivity. Copper has less resistance for a given cross-sectional area than aluminum. The conductivity ratio of pure copper to pure aluminum is 1.6 to 1 in favor of copper. Put another way, if a length of copper had a resistance of 0.01 ohm, an equivalent length of similarly sized pure aluminum wire would have a resistance of 0.016 ohm.

Reduced conductance isn’t an issue if the conductor is large enough to pass current without too much voltage drop. As of the writing of this article in July 2023, aluminum has a value of $0.97 per pound, and copper is $3.77, according to the New York Mercantile Exchange. You could use a much larger conductor with twice as much aluminum, have less resistance, and still be at almost half the cost of copper.

If you look at the power lines that run from one pole to another where you live, or the high-voltage lines that run across the country, all of these are aluminum conductors. An important consideration for the companies supplying power to your home is that aluminum weighs 0.302 times less than copper for a given conductor size. Weight savings is crucial when linemen need to work with conductors thousands of feet long. In other words, please don’t be too hard on aluminum as a conductor; it has its place. That place happens to be somewhere other than your vehicle.

The biggest problem with using aluminum as a conductor in a vehicle is corrosion. Aluminum doesn’t get along well with salt. If you live in one of the Northern states or in Canada, many areas use salt on the roads in the winter to prevent ice formation. When aluminum comes into contact with salt, or more specifically with the sodium in salt, it corrodes quickly.

We should be clear that the copper-clad aluminum, or CCA, wire sold for car audio applications combines copper and aluminum. None of the companies we’ve ever dealt with or heard of sells an all-aluminum wire for car audio purposes. One of the biggest challenges related to CCA wiring is that no manufacturer specifies the ratio of copper to aluminum. We’ve tested dozens of different CCA wire samples and seen dramatically different conductivity. The range of copper-to-aluminum ratios varies so much that we’ve measured a smaller-diameter conductor with less resistance than a larger one because it contains less aluminum.

The second problem with CCA wiring for car audio applications is that it often doesn’t meet the American Wire Gauge standards for the diameters of electrically conducting wires. You may have seen these kits sold with labels saying 4-gauge instead of 4 AWG. We’ve seen 4-gauge CCA kits with four times the resistance per foot or meter of an all-copper 4 AWG kit. It’s worth noting that several companies offer undersized pure-copper wire. It would make more sense to us to simply call a kit 5 AWG or 6 AWG, if that’s what it is, rather than 4-gauge “all-copper.”

How To Spot CCA Wire

The first thing you’ll notice when looking at CCA wire is that it weighs less than an all-copper conductor of the same size. Unless you shop for wire regularly, you’d have to compare the weight of a length of CCA wire to an all-copper counterpart. The difference is usually quite significant.

A better way to identify the difference is to look at the end of the wire. If the wire has a consistent red-orange or red-brown appearance with no traces of anything white, then it’s likely all copper. If it looks mostly white, like the bottom of a soda can, it’s copper-clad aluminum. There is a catch here: Some copper wire, especially that intended for marine applications, is tinned. This tin layer adds additional resistance to corrosion. However, it makes the appearance test less reliable. Reading the labeling on the wire to see whether it’s a marine solution will be the clue to knowing what you’re dealing with.

How To Test Wire

I watched an episode of Bigclivedotcom on YouTube where he was tearing down an inexpensive rubber-body kettle. During the inspection, he cut apart the power cable and performed a test to determine whether the wire was all-copper or copper-clad aluminum. I’d never seen this particular test before.

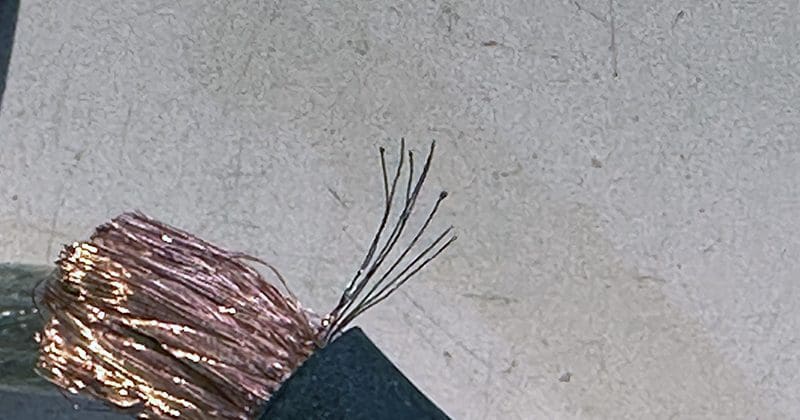

He cut off about an inch of insulation and spread the wire strands out so only a few were sticking out the side. Then he used a Bic lighter (or the equivalent) to burn the conductor strands. If the wire shrivels up quickly, it has a lot of aluminum. If the wire discolors and glows red, it’s likely mostly copper. If you want to watch the original video, check it out here. The wire testing starts two minutes and fifty-four seconds into the video. Frankly, that’s pretty neat. Depending on your curiosity about how things work, the rest of the video may or not be of interest.

So, how does this flame test work? Once again, it comes down to the differences between copper and aluminum. Aluminum has a melting point of 1,220 degrees Fahrenheit, and copper melts at 1,983 degrees. The temperature at the tip of the yellow Bic lighter flame is about 2,500 degrees, and the brightest part is about 2,200 degrees. So, if you wait long enough, you can still melt the copper.

Let’s try this test for ourselves. I scrounged around the lab for a few samples of wire and a lighter to do the test. I have pieces of what I know are all-copper wire, copper-clad aluminum wire, and wire that is likely tinned copper.

The all-copper wire we tested, including the tinned copper, glowed red at the tip but didn’t melt. The copper-clad aluminum wire didn’t shrivel as quickly as the wire in Clive’s videos, but it melted and drooped. It was obvious which was which.

Use the Best Wire You Can Afford with Your Amplifier

When it comes time to have an amplifier installed in your car, truck, boat, side-by-side or motorcycle, ensure that the technician working on your vehicle uses all-copper power and speaker wire. This type of wire will cost more than copper-clad aluminum conductors but will help your audio system function reliably. Drop by a local specialty mobile enhancement retailer today to find out what upgrades are available to make the audio system in your vehicle sound amazing!